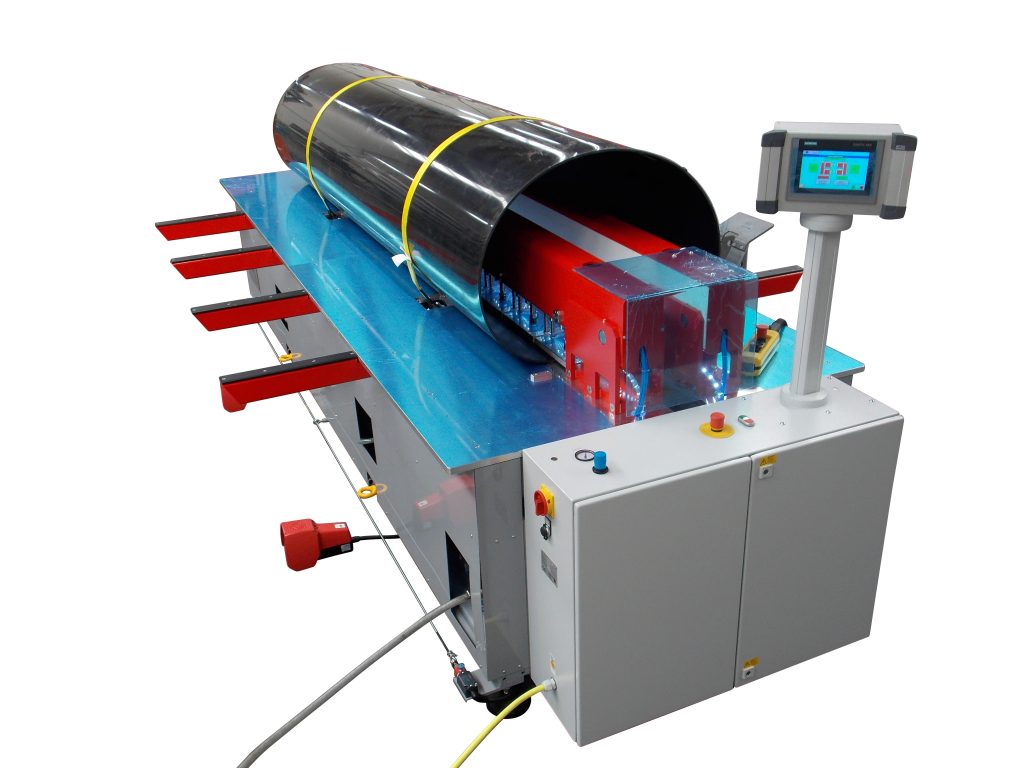

Butt-Welding Machine P-SW

The SW model range has been designed for the maximum demands placed on quality and capacity. This version has two clamping ranges on each table side as well as a travel measurement device and a travel controller. Machines of this series are fitted out with a CNC table force controller, including database. They can also be provided with an automatic 90° welding fixture at the customer’s request.

The welding cycle of this machine runs automatically.

This machine comes in the following versions:

2 m, 3 m, 4 m, 5 m or 6 m

Weldable thicknesses: 3 – 60 mm

Customized solutions possible

| Model | Working width |

Material thickness |

| 20.30 P-SW | 2.000 mm | 30 mm |

| 30.30 P-SW | 3.000 mm | 30 mm |

| 40.30 P-SW | 4.000 mm | 30 mm |

| 50.30 P-SW | 5.000 mm | 30 mm |

| 30.40 P-SW | 3.000 mm | 40 mm |

| 40.40 P-SW | 4.000 mm | 40 mm |

| 50.40 P-SW | 5.000 mm | 40 mm |

| 30.50 P-SW | 3.000 mm | 50 mm |

| 40.50 P-SW | 4.000 mm | 50 mm |

Extra P-SW equipment

- INGENIA online diagnostic system

- Illumination of the welding range

- Scale on both table sides

- Extension to a 65 mm clamping height e.g. for hollow chamber boards

- Plastic sheet lifter (only one side)

- Extra clamping range for each side (from 2 to 3 ranges)

- T-welding programme (only in association with 90° L-angle welding fixture)

- Offset compensator for establishing and balancing tensions & friction forces

- Automatic table gap adjustment

- Remote control or foot-operated switch for clamping

- Printer for drafting a DVS 2207-11-based welding record

- Acoustic signal once the welding cycle is over

- Extension arm with ball casters

- Automatic press-on unit

- Automatic 90° L-angle welding fixture

- Sheet roller

- Non-standard paint finish